Add to Cart

a Moderate hardness, pure ingredients, and large coverage;

b It does not have the shortcomings of ordinary cast steel shots such as pores and special shapes, and its service life is longer;

c The performance of this product can completely replace imported products, and the price is significantly lower than imported products, saving costs for customers, and consuming 1 kilogram of stainless steel pellets is equivalent to consuming 17 kilograms of emery sand, which is equivalent to consuming 100 kilograms of glass beads; Equivalent to consuming 3-4 kg of ordinary steel shot; equivalent to consuming 3 kg of aluminum shot and zinc shot;

d. After treatment with stainless steel shot, the surface of the casting will be smooth and rust-free, and there is no need for post-processing such as pickling, which is beneficial to environmental protection.

| Technical Parameters | Description |

|---|---|

| Tensile Strength | 1300-2400Mpa |

| Owen's Lifespan | 6500 Times |

| Application | Cleaning Surface Oxides To Increase Corrosion Resistance, Etc. |

| Bulk Density | 4.70g/m3 |

| Cleanliness | Highly Polished |

| Versatility | Suitable For Various Applications |

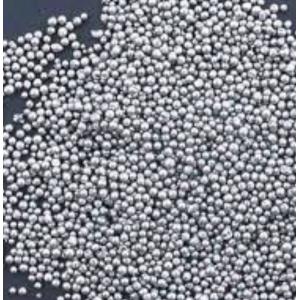

| Name | Stainless Steel Shot |

| Feature | Moderate Hardness, Pure Ingredients, Large Coverage |

| Corrosion Resistance | High |

| Abrasion Resistance | Excellent |

| Product Type | Rounded Stainless Steel Wire Cut Pills |

| Usage | Stainless Steel Shot Blasting, Stainless Steel Shot Blasting Equipment |

| Suitability | Various Applications |

Stainless steel shot is widely used in the surface shot blasting treatment of aluminum alloy, zinc alloy, stainless steel plate, non-ferrous metal casting and stainless steel casting. It focuses on the luster of the metal material and will not rust or discolor the surface of the casting. The castings after shot blasting are now clean, uniform, rust-free, and have a matt effect, without the need for cleaning, pickling and other processes. Stainless steel shot is bead-shaped and has good fluidity, which is conducive to internal circulation in the machine, ensuring that the spray processing can effectively treat the surface of the casting and hide defects on the surface of the workpiece, such as scars, scars, and mold cracks.

Large, medium and small castings: Cleaning of surface oxides to ensure good cleanliness and required roughness for subsequent processing and painting.

Steel plate pretreatment: used to remove scale, rust and other impurities.

Engineering machinery: remove rust, welding slag, and oxide scale, eliminate welding stress, increase the bonding force between the anti-rust coating film and the metal matrix, and improve the anti-rust quality.

Stainless steel plate cleaning: Steel plates of different materials require different sizes of abrasives and particle size selections.

Cleaning of steel structure parts, H-shaped steel, C-shaped steel and angle steel.

Pipeline anti-corrosion: Increase corrosion resistance and achieve the required rust removal level and tracing depth.

Shot blasting strengthening: strengthening treatment of key parts such as coil springs, leaf springs, torsion bars, gears, transmission components, bearings, camshafts, crankwheels, connecting rods, etc.

Inner packaging: 25kg/bag with inner film bag.

Outer packaging: nylon woven bag, kraft paper bag, carton.

Whole ton packaging: pallet or ton bag.