Add to Cart

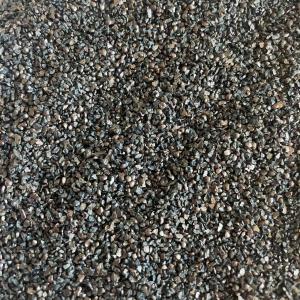

Steel Grit, also known as Steel Grit Abrasive, is a high-quality abrasive media made from steel. Its unique properties make it ideal for various blast cleaning applications, making it a popular choice for many industries.

As the name suggests, Steel Grit is made from steel, which is known for its strength and durability. This material is able to withstand high pressure and impact, making it suitable for tough cleaning tasks.

The name Steel Grit perfectly reflects the product's material and purpose. It is a grit made from steel, designed to provide effective and efficient blast cleaning results.

Steel Grit has a minimum density of 7.4g/cm3, which is significantly higher than other abrasive media. This high density allows for better impact force and results in a faster and more thorough cleaning process.

One of the key advantages of Steel Grit is its durability. The steel material ensures that it can withstand multiple uses without wearing down or losing its effectiveness. This makes it a cost-effective choice in the long run.

Steel Grit is primarily used for blast cleaning applications, where it is projected at high speeds onto a surface to remove dirt, rust, and other contaminants. Its high density and durability make it perfect for tough cleaning tasks in industries such as automotive, marine, and construction.

Low dust generation: Steel grit is designed to minimize dust generation during surface treatment processes. This feature is particularly important in environments where dust control is critical, such as cleanrooms or sensitive manufacturing facilities.

Customizable hardness levels: Steel grit can be manufactured with different hardness levels to suit specific application requirements. By adjusting the composition and heat treatment processes, the hardness of the grit can be tailored to achieve optimal results for different materials and surface conditions.

Controlled particle size distribution: Steel grit can be produced with a tightly controlled particle size distribution, ensuring consistency in the abrasive action and surface finish. This allows for precise control over the surface roughness and texture, meeting specific requirements for different applications.

Specialized coatings: Steel grit can be coated with various materials to enhance its performance in specific applications. Coatings such as zinc, copper, or aluminum can improve the grit's resistance to wear, increase its lifespan, or provide additional properties like anti-corrosion or anti-static capabilities.

Environmentally friendly options: Eco-friendly variants of steel grit are available, which are manufactured using recycled steel or have lower environmental impact. These options meet sustainability goals by reducing resource consumption and minimizing waste generation.

Compatibility with automated systems: Steel grit can be designed to be compatible with automated surface treatment systems, enabling efficient and precise processing in industrial settings. This compatibility enhances productivity, reduces labor costs, and ensures consistent results.

In summary, steel grit differentiates itself through features such as low dust generation, customizable hardness levels, controlled particle size distribution, specialized coatings, environmentally friendly options, and compatibility with automated systems. These characteristics provide versatility, improved performance, and environmental considerations in various surface treatment applications.

Surface roughening for adhesive bonding: Steel grit can be used to create a roughened surface on metal substrates for improved adhesion of adhesives. This is particularly important in industries such as aerospace and automotive, where strong and reliable bonding is necessary for structural integrity.

Surface preparation for thermal spraying: Steel grit is utilized in the surface preparation process for thermal spraying, where a coating material is applied to a metal surface using high-velocity particles. The abrasive action of steel grit helps to create a clean and roughened surface for better adhesion and bonding of the sprayed coating.

Surface preparation for metal etching: Steel grit can be employed in metal etching processes to prepare the surface for subsequent etching or engraving. The angular particles of steel grit help to remove surface contaminants and provide a textured surface, improving the quality and precision of the etching or engraving results.

Surface preparation for metallographic analysis: Steel grit is used in metallographic analysis to prepare metal samples for microscopic examination. By removing surface layers and creating a clean surface, steel grit enables accurate and detailed analysis of the metal's microstructure, grain size, and other characteristics.

Surface preparation for non-destructive testing (NDT): Steel grit is used in surface preparation for NDT methods such as magnetic particle testing or liquid penetrant testing. The abrasive action of steel grit helps to remove surface contaminants and create a clean surface that allows for effective detection of defects or discontinuities in the metal.

Surface preparation for precision machining: Steel grit can be utilized in surface preparation for precision machining processes, such as milling or turning. By creating a uniform and textured surface, steel grit facilitates better chip evacuation, reduces tool wear, and improves the surface finish of the machined components.

Inner packaging: 25kg/bag with inner film bag.

Outer packaging: nylon woven bag, kraft paper bag, carton.

Whole ton packaging: pallet or ton bag.

A: The brand name of this product is longkuang.

A: The model number of this product is 0.075-2.8mm.

A: This product is manufactured in China.

A: Yes, this product is certified with iso9001.

A: The minimum order quantity for this product is 1000kg.

A: Yes, the price for this product is negotiable.

A: This product can be packaged in ton bags, wooden boxes, wooden pallets, or barrels.

A: The delivery time for this product is determined based on tonnage and specification model.

A: The payment terms for this product are T/T and L/C.

A: The supply ability for this product is 50000ton/year.